← Nos solutions

Machine d''inspection automatisée pour le mirage "human like" de Vials et Seringues

Découvrez Eagle, la solution d''inspection automatisée pour le mirage "human like" de Vials et Seringues

The equipment offer the following functionalities:

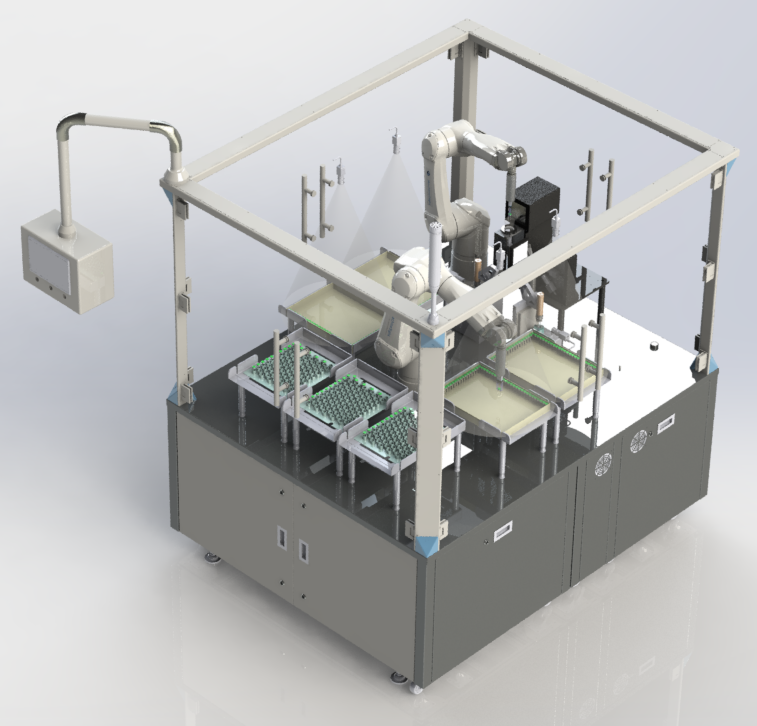

• Take vials from Akylux or denest vials or syringes from a nest

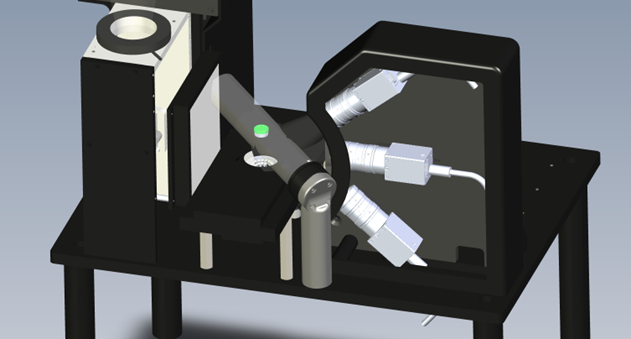

• Make the products pass through no less than 6 color cameras and their lighting to cover all areas while taking a minimum of 24 images by camera

• Place back the accepted units in Akylux or nest

• Sort and place the rejected units in three separated Akylux or nests

• Offer a throughput performance of 10 units/minute

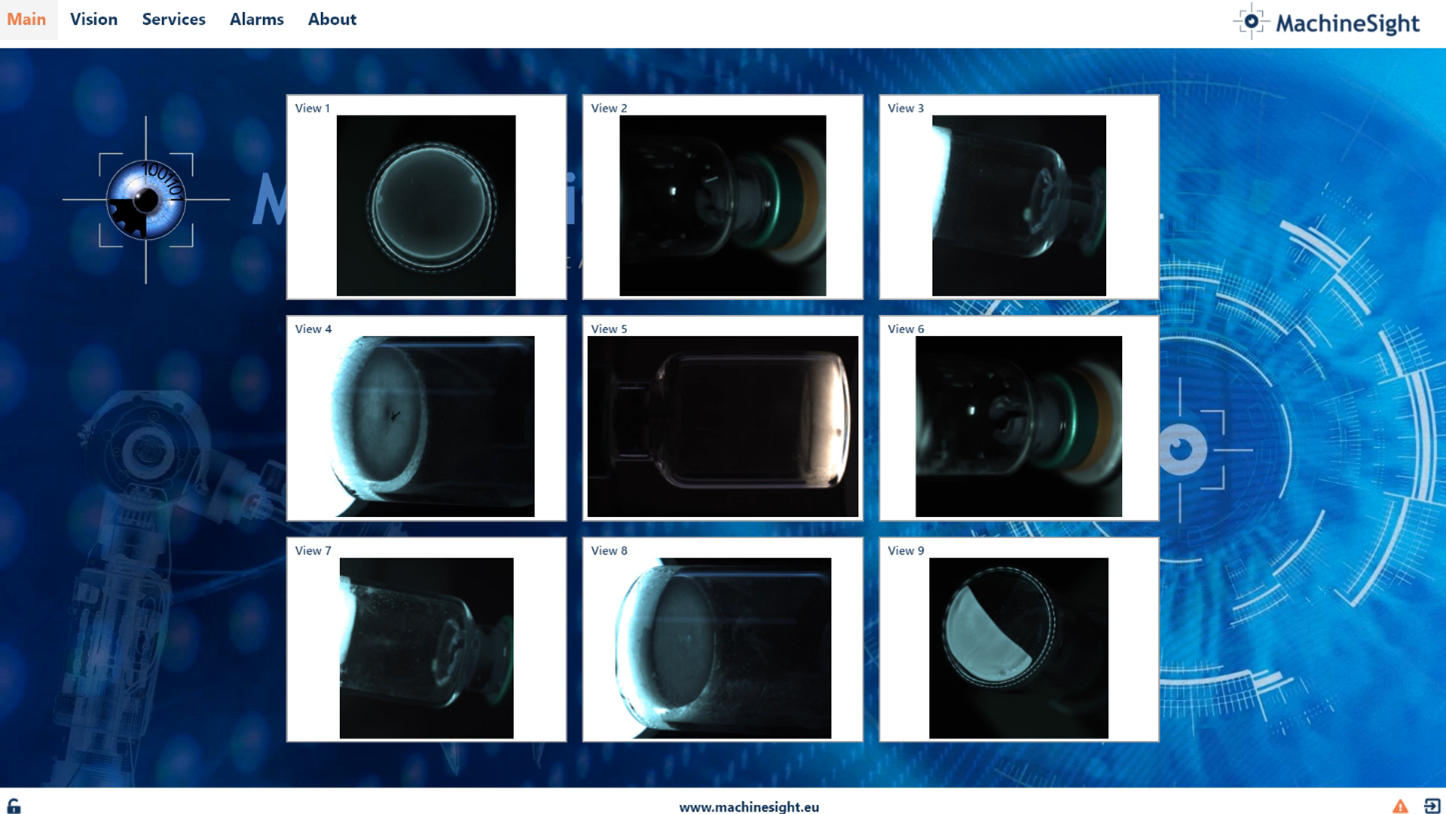

The vision controller, based on Occulus.AI, that will be distributed over several systems to reach the required performance will act to:

- manage the image acquisition of 10 cameras (6 are used for inspection and 4 for pick/place operations)

- process the images, including “traditional” vision operations (filtering, matching…) and deep learning inferences

- store the images, with their metadata; it is used as a temporary local storage and the files are transferred to local FileServer (HMI PC) by a background task (low priority)

- communicate with the PLC

o Input recipe id (per process)

o Input product id (per workstation)

o Input start/stop/mode

o Inputs … TBD

o Output state

o Output alarms

o Output results

o Outputs … TBD

o Protocol will be based on OPC-UA

The FileServer exchange is envisioned as:

- Input model files (with a checksum to verify integrity); they are localized on the FileServer to avoid local duplication

- Output images: their absolute paths and directories are related to their classification results.

All the cameras are triggered by hardware.

The vision system includes four types of inspection stations.

Each association of a viewing angle, a specific illumination condition and a unit position and orientation will be called a “Pose”. Each pose requires a specific implementation of the inspection algorithm.